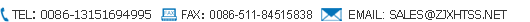

Industrial Elevator Bucket

Material: HDPE/NYLON/UHMWPE/PU

Features:

•Optimum industrial style elevator bucket with a heavy reinforced lip and

corners and a thickened back wall for mounting strength.

•Well suited to conveying of ore, sand, gravel, coal, fertilizer, clay, salt,

limestone and cements or any product.

•Weight reduction of up to 80% compared to traditional cast iron elevator

buckets.

•Using less energy due to lighter material being used.

•Up to 25% more capacity than cast iron elevator buckets.

•Extended bucket and belt life, less maintenance, less elevator downtime.

•Cleaner discharge, reduced build-up in the bottom of the buckets.

•Non corrosive, non sparking, heat resistant, impact and abrasion resistant.

Using Recommendations

•Recommended minimum bucket spacing: bucket projection "B" × 2.

•Mounting holes can be customized on request.

|

Model |

Bucket Dimension* (mm) |

Capacity(L) |

||||||

|

Length |

Proj. |

Depth |

D |

D1 |

E |

H |

||

|

TD400 |

415 |

213 |

213 |

45 |

35 |

75 |

/ |

7.20 |

|

TD315 |

338 |

213 |

200 |

40 |

40 |

40 |

/ |

7.10 |

|

TD250 |

264 |

233 |

220 |

40 |

40 |

80 |

/ |

4.95 |

--------------------------------------------------------------------------------------------------------------------------------------

Hengtong Elevator Buckets

•High impact, abrasion resistance, no-corrosion, smooth surface, FDA Food proved.

•Less weight, prolong service life of buckets and belts, reduce elevator consumption.

•A direct replacement for many other international brands.

•Unique elevator bucket design with multiple patents.

•Our elevator buckets are well regarded, worldwide for high cost /quality ratio.

|

Material |

HDPE |

Nylon 6 |

UHMWPE |

PU |

Mild Steel |

Stainless |

|

Cost |

1 |

3 |

3 |

4 |

2 |

4 |

|

Wear Resistance |

1 |

2 |

3 |

4 |

3 |

4 |

|

Impact Resistance |

1 |

2 |

2 |

2 |

2 |

2 |

|

FDA Food Approved |

Yes |

Yes |

Yes |

No |

No |

No |

|

Max Temp℃ Continuous |

70 |

100 |

70 |

60 |

180+ |

250+ |

|

Max Temp℃ Peak |

80 |

120 |

80 |

70 |

220 |

400 |

Remark: Code 1=low 4=high

•HDPE: Tough and lexible, suitable for handling grains, foodstuffs, and other products with no sharp edges and material that has a bulk density of less than1g/cm³ .

•Nylon: High impact and abrasion resistance, better heat resistance and are well suited for handling hot, abrasive and sticky products.

•UHMWPE: Extremely abrasion resistance, corrosion resistant, impact absorbing properties, low temperature resistant, sanitary (FDA approved), Non-caking and sticking, now water absorption, light weight properties.Higher cost performance products.

•PU: Extremely abrasion resistance, tough and lexible, and are suitable for handling sharp, cutting and sticky products.

•Mild Steel: General purpose, long life, well suited to agricultural and industrial products.

•Stainless Steel: Food grade, corrosive resistance, suitable for food and high temperature applications.

-----------------------------------------------------------------------------------------------------------------------------------