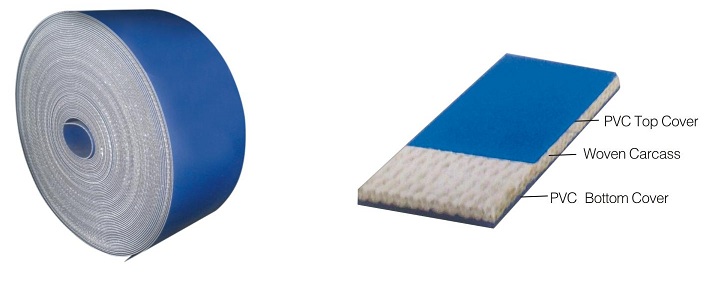

PVC Elevator Belt

Key Features and Benefits:

• Multiply inter-woven carcass keeps synchronous in the course of weaving, impregnation, plasticization and paste. The structure is stressed in balance. The dipping elastomer could bind all the yarn, composing a close-grained and flexible carcass. No excessive pulling and compression. Keep a good running trail and not easy to off track.

• Compared to the rubber elevator belt, it’s uniformly stressed to ensure the strong elevating capability. No peeling off both on the cover rubber and between ply and ply with superior tear resistance.

• Good bolt retention and makes a strong joint between the bucket and belt.

• With better properties such as resistance to oils, chemicals, dumps and wear compared to the rubber elevator belt.

• The belt is of weight light, strong structure and low driving power. With superior anti-elongation and lower extension rate compared to the rubber elevator belt.

• Its fire retardant and anti-static property guarantee safer working condition while running.

• Well suited to grain handling industries.

Technical Specifications:

|

Model |

Color |

Rated Tensile Strength |

Thickness (mm) |

Working |

Elongation at |

Recommended |

|

PVC400 |

Cover:Blue |

500 |

5.2—5.5 |

-15~+85 |

0.60 |

100 |

|

PVC600 |

700 |

6.2—6.5 |

0.60 |

150 |

||

|

PVC800 |

900 |

7.0—7.5 |

0.70 |

250 |

||

|

PVC1000 |

1100 |

9.0—9.5 |

0.70 |

350 |

Performance Of PVC cover:

|

Index |

Units |

Value |

|

Tensile Strength |

MPa |

≥20 |

|

Adhesion Strength for Cover Against Carcass |

N/mm |

≥7.0 |

|

Elongation at Break |

% |

≥300 |

|

Abrasion Loss |

mm³ |

≤100 |

|

Electrical Conductivity |

MΩ |

≤300 |

|

Flammbility (with flame) |

s |

≤10 |

|

Flammbility (without flame) |

s |

≤30 |

Remark: Special size belt can be made as customer's requested.

----------------------------------------------------------------------------------------------------------